Process Control Lab - Draft Version

Focus

Design and implementation of controllers for different processes.

Infrastructure

Major Equipment

- Temperature process trainer

- Pressure process trainer

- Flow process trainer

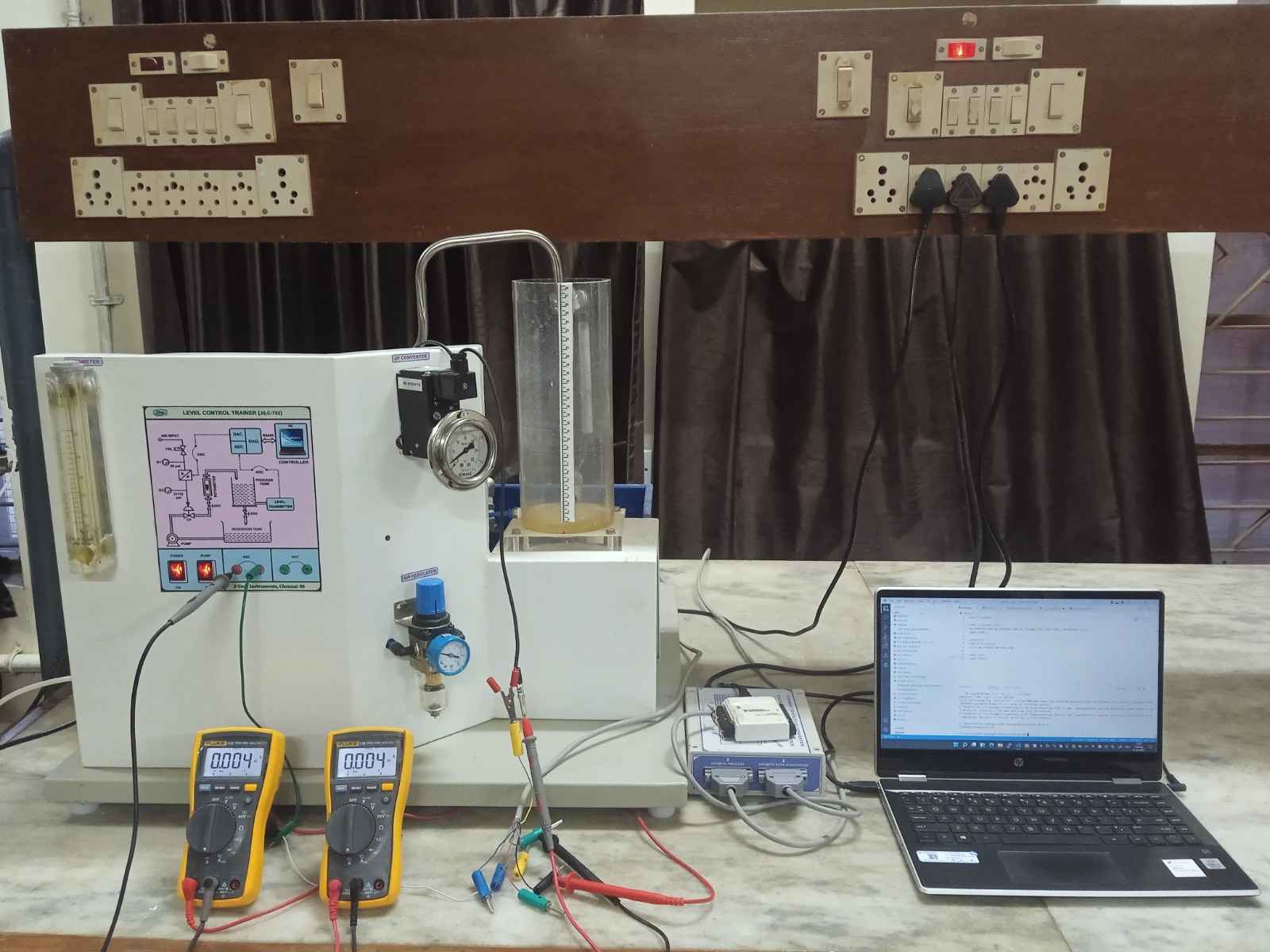

- Level process trainer

- Multi process trainer: System to study Feed-forward, cascade and ratio control schemes

- System to study control valve characteristics

- Programmable logic controller with computer interface

- Model of Water Distribution Set-up

- Hybrid Tank system

- Data acquisition cards/modules

- Facility for centralized pneumatic and water supply

- Set-up for sensor less flow measurement

- Personal Computers

Softwares

- NetSim (Network Simulator)

- MATLAB

- CIROS - Virtual Learning Environments (FESTO)

List of Experiments

- Identification and design of different PID controller for FOPDT and SOPDT process using standard techniques and evaluate qualitative & quantitative performance.

- Study of different real time process trainers and development of P&ID for the above processes.

- Design and verification of combinational & sequential circuits using PLC.

- Design of PID controller for a Level Process/ Temperature/ Flow/ Pressure process stations and evaluate servo/ regulatory responses.

- Pressure to Current & Current to Pressure Convertor using real time process trainer.

- Develop a PLC program using timer and counter.

- Design of cascade and feed forward controller in simulation platform.

- Study of different PID controller parameters using real time process trainer.

- Study of control valve characteristics.

- Develop a PLC program for any practical application.